Logistics 4.0 solutions

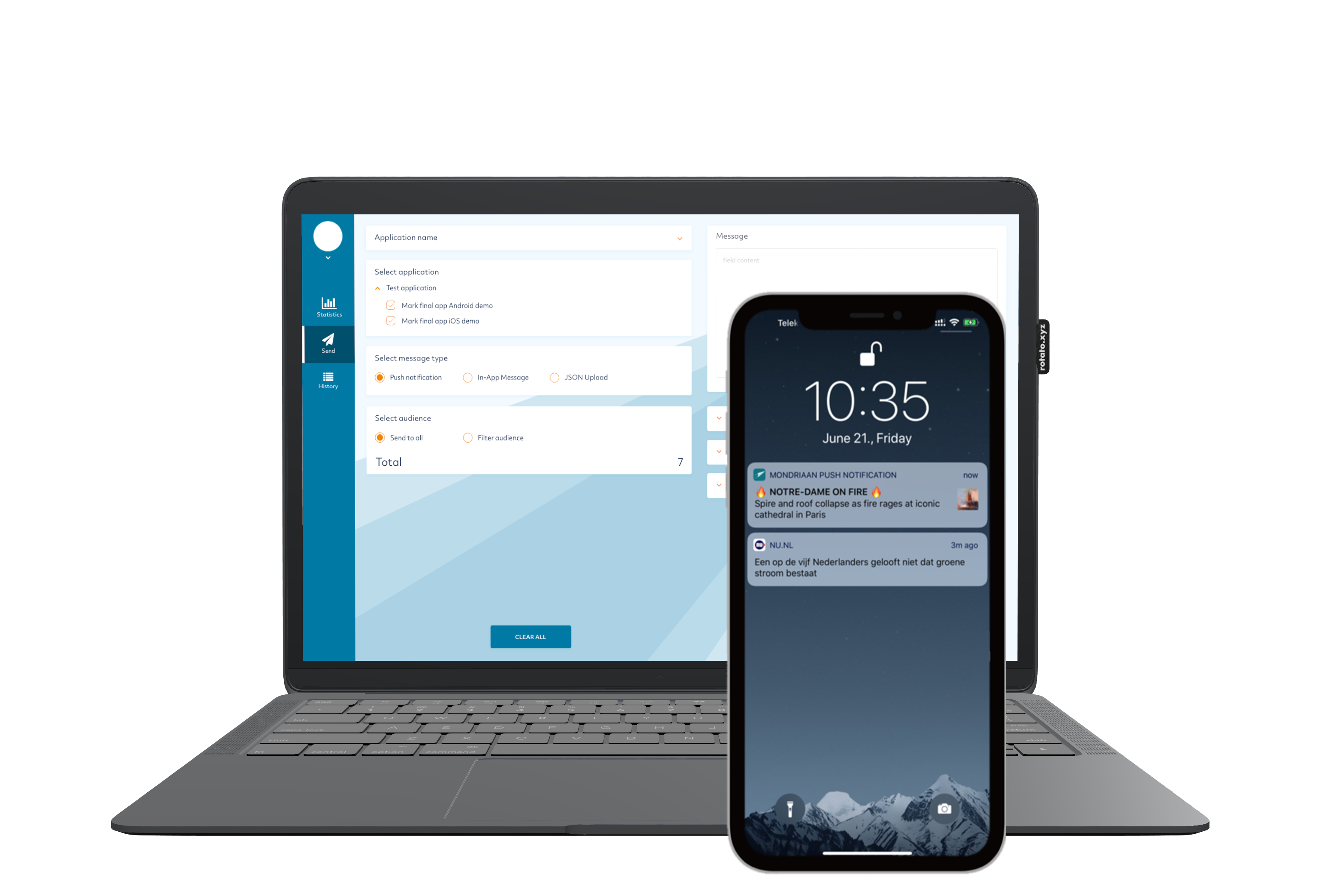

Mobile-first logistics operation with connected SKU journey

by MONDRIAAN

logistics 4.0 solutions

Mobile-first logistics operation with connected SKU journey

by MONDRIAAN

Work with MONDRIAAN ON

INCREASED AUTOMATION

Sensor data collected and visualized on user-friendly interfaces for semi-automatized decision making

REDUCED COSTs

Errors prevented, decreasing waste generated by misdelivered or not delivered orders

Increased transparency

Connected processes for holistic traceability of inventory, fleet and personnel in and out of your warehouse

Optimized resources

Resource utilization increased via correctly completed routes supported by continuous monitoring

Work with MONDRIAAN ON

Increased automation

Sensor data collected and visualized on user-friendly interfaces for semi-automatized decision making

Reduced

costs

Errors prevented, decreasing waste generated by misdelivered or not delivered orders

Increased transparency

Connected processes for holistic traceability of inventory, fleet and personnel in and out of your warehouse

Optimized

resources

Resource utilization increased via correctly completed routes supported by continuous monitoring

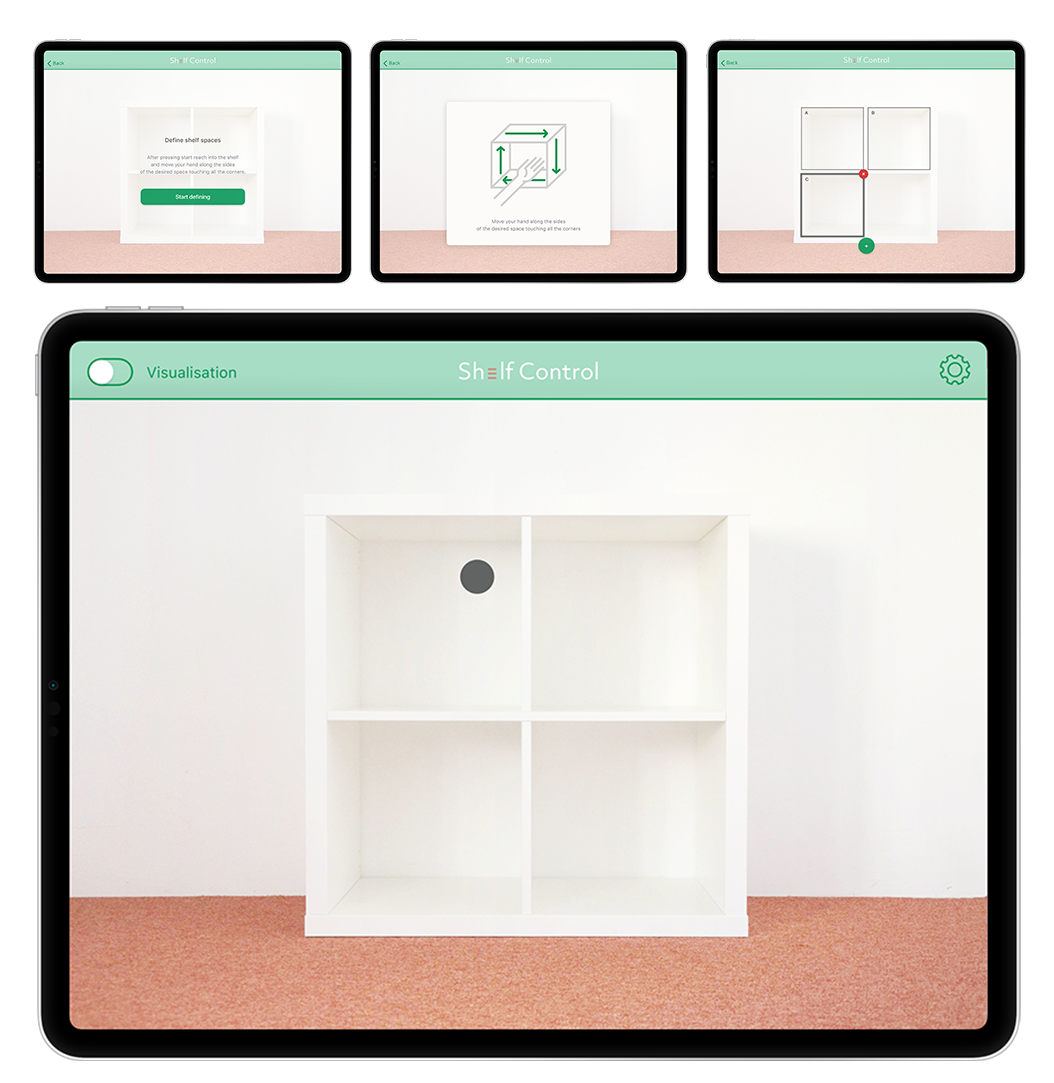

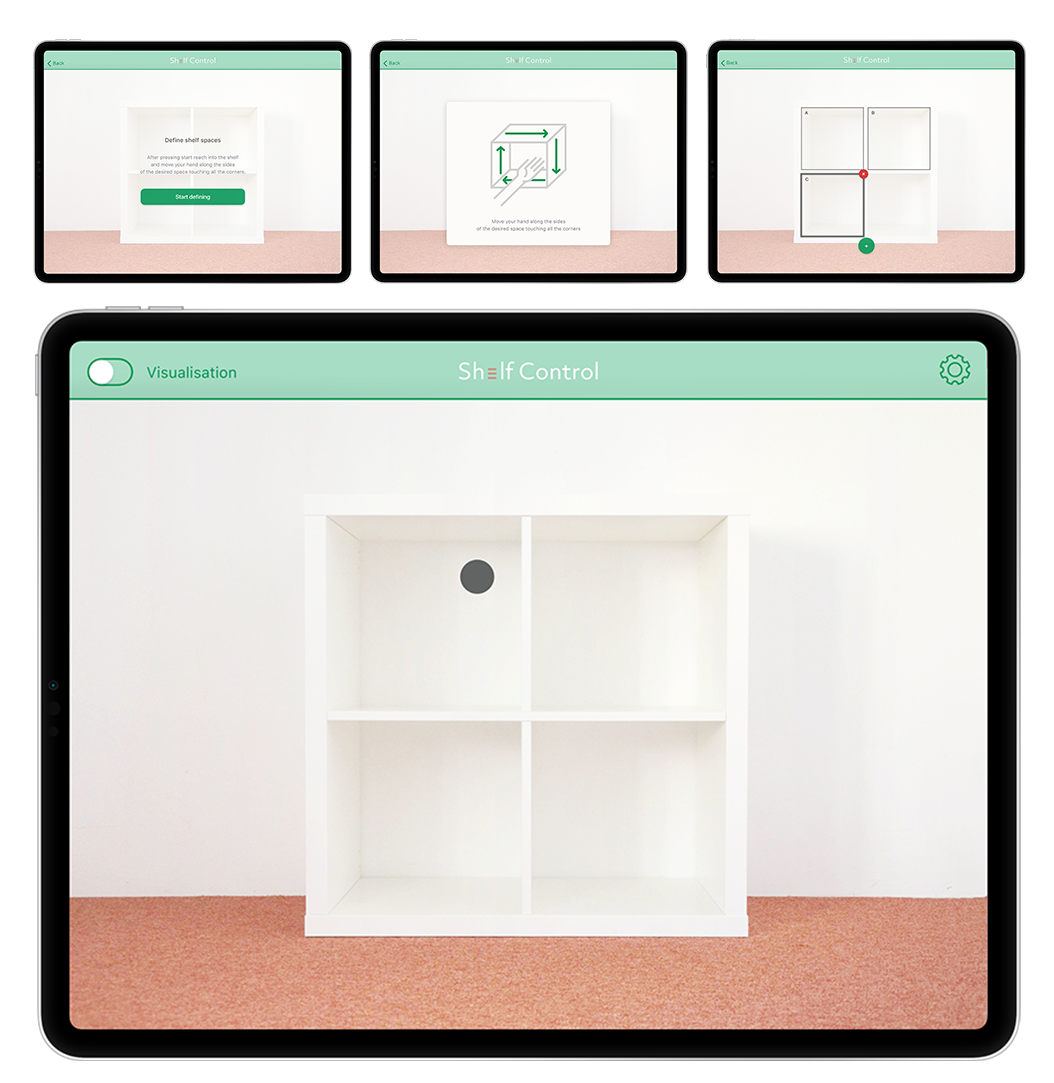

Shelf Control

Problem

Incorrect completion of manual commissioning routes and warehouse theft resulted in numerous not delivered or misdelivered orders, causing significant support costs and missed revenues for our partner.

Answer

MONDRIAAN implemented laser technology for continuous shelf monitoring, helping operators to correctly finish handpicking and supervisors to get notified in case of failures.

Solution

Shelf Control – extended by Pick-to-Light – identifies when a hand or fork enters the control areas and notifies the related parties on the desired interface (mobile or voice) upon mistake. Supervisors also benefit from an easy-to-use tablet application to flexibly define the areas to be examined.

Results

The solution improved handpicking accuracy, decreased warehouse theft, while opening the horizon for warehouse-wide real-time inventory control.

Contribution

iOS application | UX&UI design | LiDAR sensor integration | back-end development

Shelf Control

Solution

Shelf Control – extended by Pick-to-Light – identifies when a hand or fork enters the control areas and notifies the related parties on the desired interface (mobile or voice) upon mistake. Supervisors also benefit from an easy-to-use tablet application to flexibly define the areas to be examined.

Results

The solution improved handpicking accuracy, decreased warehouse theft, while opening the horizon for warehouse-wide real-time inventory control.

Contribution

iOS application | UX&UI design | LiDAR sensor integration | back-end development

Product diagnostics

Problem

Manual registration of incoming products demanded significant labour at our FMCG logistics partner, whilst not providing any information about SKU weight and volume.

Answer

MONDRIAAN selected a proven diagnostic gate which improves this lagging process, built a custom middleware with outgoing endpoints to forward the parameters of the hardware into in-use logistics databases.

Solution

The operator moves each SKU to the conveyor of the diagnostics gate which precisely measures the weight and volume parameters of the object. Besides, the product title, SKU number and barcode are registered following the conventional process.

Results

Due to this quick solution, warehouse and fleet capacity utilization were optimized.

Contribution

middleware | diagnostic gate integration

Product diagnostics

Answer

MONDRIAAN selected a proven diagnostic gate which improves this lagging process, built a custom middleware with outgoing endpoints to forward the parameters of the hardware into in-use logistics databases.

Solution

The operator moves each SKU to the conveyor of the diagnostics gate which precisely measures the weight and volume parameters of the object. Besides, the product title, SKU number and barcode are registered following the conventional process.

Contribution

middleware | diagnostic gate integration

RFID-based inventory management

Problem

Insufficient control at the packing stage led to issues in order fulfilment, particularly due to the lack of pallet traceability.

Answer

MONDRIAAN proposed using RFID tags on correctly prepared pallets to see which pallets belong to the given delivery.

Solution

Building on a mobile-first perspective, warehouse workers received simple-to-use mobile apps to overview which pallets belong to each delivery, and with the help of RFID scanners at the dispatch gates errors are discovered if a pallet is missing, or is not in the right truck. The weight and volume of each load are also calculated so that truck capacity can be optimized.

Results

MONDRIAAN’s partner enjoys improved fulfilment accuracy and better fleet capacity utilization due to RFID-based inventory management.

Contribution

iOS application | UX&UI design | RFID reader integration | back-end development

RFID-based inventory management

Solution

Building on a mobile-first perspective, warehouse workers received simple-to-use mobile apps to overview which pallets belong to each delivery, and with the help of RFID scanners at the dispatch gates errors are discovered if a pallet is missing, or is not in the right truck. The weight and volume of each load are also calculated so that truck capacity can be optimized.

Results

MONDRIAAN’s partner enjoys improved fulfilment accuracy and better fleet capacity utilization due to RFID-based inventory management.

Contribution

iOS application | UX&UI design | RFID reader integration | back-end development

MONDRIAAN’s connected logistics journey

MONDRIAAN’s connected logistics journey

Get in touch with MONDRIAAN for connected logistics solutions.

Get in touch with MONDRIAAN for connected logistics solutions.

CONTACT US

1023 Budapest

Ürömi utca 43

Industries

Blog

CONTACT US

1023 Budapest

Ürömi utca 43

Industries